Textile customization has become a real trend for both businesses and individuals seeking unique creations. Whether for clothes, accessories or decorative objects, the choice of custom fabric and the printing method is essential to ensure a quality result. In this article, we will guide you through the key steps to customize your textile products successfully, focusing on the most suitable fabrics for printing and the most effective techniques for an impeccable finish. Also discover tips for preparing your print files and tips for choosing materials that will enhance your creations. Read more to turn your ideas into creative projects through textile printing!

Understand Custom Textile Print

Definition and Importance of Textile Printing

THE'custom textile printing makes it possible to create unique products from virgin fabrics. Whether you're a fashion designer, an event entrepreneur or an individual passionate about sewing, this technique offers you the possibility to design tailor-made pieces, whether it be clothing, accessories or advertising objects. The appeal of personalized textile printing lies in its ability to transform a simple idea into a tangible and unique product. In addition to offering a wide range of creative possibilities, it can also meet specific design and quality needs.

Different Types of Textiles for Printing

Before delving into the details of printing techniques, it is crucial to understand the different types of textiles you can use to customize your creations.

- Synthetic fabrics : Fabrics like polyester are perfect for sublimation printing, as the inks penetrate directly into the fibres of the fabric, creating vibrant and durable designs.

- Cotton : A popular choice for clothing, printing on cotton gives a natural look, soft to the touch, and offers excellent breathability. Direct printing on cotton is ideal for this material.

- Mixed textiles : For versatile products, mixed fabrics (such as cotton/polyester) offer an excellent compromise in terms of comfort and durability, while being compatible with several printing techniques.

Textile Printing Techniques

Digital Printing: Advantages and Disadvantages

THE'digital printing is one of the most popular methods for customizing textiles. It uses specific inks applied directly to the fabric using a printer. This is a perfect option for small series and complex designs.

Benefits:

- High accuracy for detailed reasons.

- Possibility to customize each piece in a unique way.

- No limit in the color range.

Disadvantages:

Less economical for large series compared to other techniques such as screen printing.

DTF printing: Innovative Technology

LDTF printing is an innovative technique for transferring detailed designs across a wide range of textiles, including dark fabrics.

Benefits:

- Excellent grip on various textiles, including dark fabrics.

- Great richness of colors and details.

- Good elasticity.

- Resistance to washing.

Disadvantages:

- Processes requiring specific equipment.

- Higher cost for small series.

- Finish slightly in relief compared to other techniques such as sublimation.

Screenwriting: A Traditional Technique

The screen printing is a traditional technique that consists of applying ink through a screen on the fabric. It is ideal for simple designs and plain colors.

Benefits:

- Reduced cost for large quantities.

- Durable finish and professional quality.

Disadvantages:

Less suitable for complex or multicoloured patterns.

Requires longer preparation time.

Less resistant in time.

Impression by Sublimation: For dazzling Finishes

The sublimation is ideal for synthetic textiles such as polyester. This method transfers inks to the fabric using heat, creating vibrant and durable designs.

Benefits:

- Bright colors and an excellent visual rendering.

- Touch soft, without surface effect.

Disadvantages:

- Only works on synthetic fabrics.

- Less suitable for small series.

Embroidery : The Elegant and Durable Touch

The embroidery offers a high-end finish and is ideal for logos or delicate details on clothing or accessories such as caps and bags.

Benefits:

- Luxurious and elegant look.

- Very durable and resistant to washing.

Disadvantages:

Less flexible than other techniques for complex reasons.

Flocage: A Unique Texture Effect

The flocking allows to apply letters or logos with a velvet texture on the fabric. This is an excellent option for original and striking creations.

If you want to customize fabrics with a specific logo, discover our complete guide on how to print a logo on fabric, a key step to create unique products.

Benefits:

- Unique visual and tactile effect.

- Suitable for small series.

Disadvantages:

Less resistant than other techniques such as screen printing.

To learn more about the latest trends and innovations in textile digital printing, check out our article on major advances in this technology.

How to Choose the Good Textile to Customize

Assess Your Project Needs

When choosing a textile to customize, it is essential to consider the objective of your project. If you are a fashion designer, you may prefer natural fabrics such as cotton for light and comfortable creations. For promotional events, more resistant, inexpensive textiles, such as mixed fabrics or synthetic fabrics, can be more suitable.

Criteria for Selecting Your Fabric

- The Design Type : Detailed drawings often require fabrics adapted to digital printing or sublimation.

- Comfort and Sustainability : For clothing, choose breathable and resistant fabrics such as cotton or cotton blends.

- The budget : If you have to print in large quantities, some materials will be more economical.

Durability and Maintenance of Printed Textiles

Printed textiles require specific maintenance to preserve the quality of printing. For example, sublimation or flocking impressions may require cold washing to avoid color degradation.

Creating a Custom Textile

Steps to Imagine and Design Your Design

- Set Your Concept Think about the goal of your project (mode, advertising, event).

- Choose Printing Technique : Depending on the complexity of the design and the type of textile, choose the method that best suits your needs.

- Create Your Design : Use tools such as Photoshop, Illustrator or online design platforms offered by your provider to create unique patterns.

Graphic Design Tools and Software

To achieve optimized designs, it is essential to use professional software or intuitive creative tools like those offered by Print Fabrics. These tools make it easy to visualize your design on the final product and adjust it before printing. Do not hesitate to view our page'aid for creation for more information.

Preparing Files for Printing

When submitting your design, make sure it meets the specifications of our digital printers. This includes resolution, file formats (usually .png, .jpg, .ai, etc.) and design dimensions. For this, we invite you to consult our printing guide.

Examples Inspirants of Custom Textile Printing Projects

- Clothing for Special Events and Enterprises Create custom t-shirts or sweatshirts for your events or to offer your employees. Custom printing is also ideal for companies looking to promote their brand through advertising.

- Accessories and Promotional Products Offer custom bags, caps, tote bags for your events or as corporate gifts. These accessories are perfect to spread your message while offering useful products.

- Unique Creations by Local Artists If you are an artist or creator, personalized textile printing allows you to share your creations with the world, whether in clothing, objects or art.

Custom Textile Print FAQ

What types of products can be printed?

Many products can be customized, such as t-shirts, sweatshirts, bags, caps, cushion fabrics, cloths, curtains and many other textile accessories.

What is the average time for custom orders?

The delay depends on the complexity of your order and the printing method chosen. Generally, it takes only a few days.

How to guarantee the quality of printing?

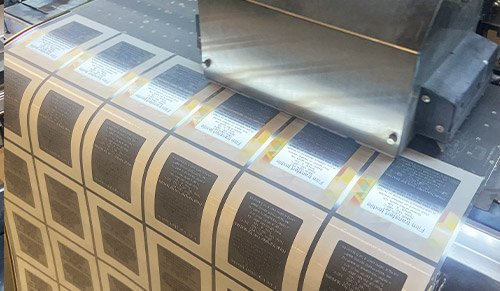

Print fabrics uses modern and high quality machines, as well as durable inks. Make sure to provide files with high resolution to ensure optimal rendering and ask for a BAT to be reassured about the quality of your print file.

If you are in the process of preparing your customization project, make sure you are master the preparation of print files to ensure an optimal result. Discover our complete guide to prepare the perfect textile print file.

What are the costs associated with custom textile printing?

Costs vary according to the chosen technique, quantity ordered and type of textile. Wholesale orders often benefit from interesting discounts. In fact, Print Fabrics offers a decreasing price from 10 meters on printing on fabric, as well as advantageous prices on the quantities of textiles.

How to manage returns or quality issues?

Before placing an order, check the return conditions and guarantees offered by the supplier to avoid surprises.

Ready to Launch Your Textile Print Project?

If you are ready to bring your ideas to life, don't wait to create your custom products. Whether you are a creator, a company or an individual, the possibilities offered by personalized textile printing are endless. Explore our options and start ordering your custom printed fabrics today!

Conclusion:

In summary, the textile customization offers endless possibilities to create unique products, whether for clothing accessories, or decorative objects. Choose the right custom fabric and mastering textile printing techniques are key steps to ensure quality rendering. By applying the tips we have shared with you on the preparation of print files and the choice of materials, you will be able to make durable and aesthetic creations. Remember thattextile printing is not only a way to add a personal touch, but also an excellent way to strengthen the visual identity of your products. So what are you waiting for to launch your projects and explore the many possibilities of textile customisation at your disposal?

0 commentaires